HPMC for Tile Adhesive

Tenessy - Reliable HPMC Supplier

Tenessy HPMC for Tile Adhesive

TENESSY Hydroxypropyl Methylcellulose (HPMC) is a high-performance cellulose ether made from natural cotton cellulose, specially designed to improve the rheology, adhesion, and workability of tile adhesive formulations.

In modern tile installation systems, tile adhesive must meet multiple performance requirements — strong bonding, good slip resistance, sufficient open time, and easy workability. TENESSY HPMC helps manufacturers achieve these properties consistently and cost-effectively.

The Functions of HPMC in Tile Adhesive

Tile adhesive is a cement-based drymix product used to bond ceramic tiles, porcelain tiles, or stones to walls and floors. HPMC acts as a key functional additive, optimizing water retention, consistency, and adhesion, while improving application efficiency and product stability.

- Water Retention: Keeps water in the mix for complete cement hydration and strong bonding.

- Workability: Improves lubrication and spreadability for smoother application.

- Sag Resistance: Prevents tile slipping on vertical surfaces for precise alignment.

- Open Time Extension: Retains moisture longer, allowing more time for tile positioning.

- Adhesion Enhancement: Strengthens the bond between adhesive and substrate for lasting performance.

- Crack Prevention: Increases flexibility and reduces shrinkage during curing.

Why Tile Adhesive Needs HPMC

In modern construction, ready-mixed tile adhesives outperform traditional sand-cement mortars — but only if the cellulose ether in the formula is high quality.

Without HPMC

- Adhesive dries too quickly, reducing bond strength.

- Tiles slide or slump on walls.

- Poor workability and uneven spreading.

- Reduced open time, increasing rework.

With TENESSY HPMC

- Excellent water retention keeps adhesive workable longer.

- Tiles stay firmly in place after installation.

- Smooth consistency ensures uniform application.

- Strong, durable bond after curing.

Recommended HPMC Grades for Gypsum Plaster

TENESSY™ offers a full range of HEMC grades to meet different performance needs in tile adhesive formulations—from standard interior applications to high-performance, heat-resistant systems. Each grade delivers optimal water retention, slip resistance, and workability to ensure reliable and consistent results.

HPMC MPT60

Medium viscosity grade offering excellent water retention and smooth workability for standard tile adhesive.

HPMC MPT80

Balanced grade providing ideal open time, sag resistance, and consistent adhesion for high-quality tile adhesives.

HPMC MPT100

High viscosity grade ensuring maximum bonding strength, extended open time, and superior vertical slip resistance.

Performance Advantages of TENESSY HPMC

- Excellent Water Retention: Ensures proper hydration of cement and bonding agents for stronger adhesion and fewer cracks.

- Smooth Workability & Lubrication: Improves flow and trowelability, reducing labor and ensuring consistent layer thickness.

- Extended Open Time & Adjustment Time: Provides longer working time for easy tile adjustment without losing bond strength.

- Superior Sag Resistance: Maintains precise tile alignment on vertical surfaces, speeding up installation.

- Enhanced Bonding Strength & Durability: Creates strong adhesion and long-term stability under thermal or moisture stress.

- Stable Rheology & Consistency: Prevents segregation or bleeding for uniform quality during production and application.

Applications of HPMC in Tile Adhesive

TENESSY HPMC is suitable for all types of cementitious tile adhesive formulations, including:

- C1 Standard Tile Adhesive: For ceramic tiles, wall, and floor installation.

- C2 Improved Tile Adhesive: For large-size porcelain tiles and heavy-duty applications.

- Flexible Tile Adhesive: Ideal for substrates with thermal movement or vibration.

- Fast-Setting Adhesive: Designed for time-critical projects.

Our cellulose ethers are compatible with polymer additives (RDP), fillers, and other modifiers commonly used in drymix adhesive production.

Other HPMC Applications

Tennessee Hydroxypropyl Methylcellulose (HPMC) improves the workability, water retention, and bonding strength of various building materials, delivering reliable performance in self leveling, wall putties, gypsum plaster, exterior insulation and finish systems (EIFS), and other dry-mix products.

Partner with Tenessy - Trustworthy Cellulose Ether Manufacturer

Why Choose TENESSY as Your HPMC Supplier

Consistent Quality and Reliable Performance

Strict control over viscosity, purity, and substitution levels ensures dependable quality across every batch.

Tailored Solutions for Different Adhesives

We provide customized HPMC grades optimized for various formulations — from economy-grade C1 to high-performance C2 systems.

Technical Expertise and Formulation Support

Our technical team assists in adjusting formulations to meet your regional standards and performance goals.

Global Supply Capability

With stable production lines and efficient logistics, TENESSY ensures on-time delivery to customers worldwide.

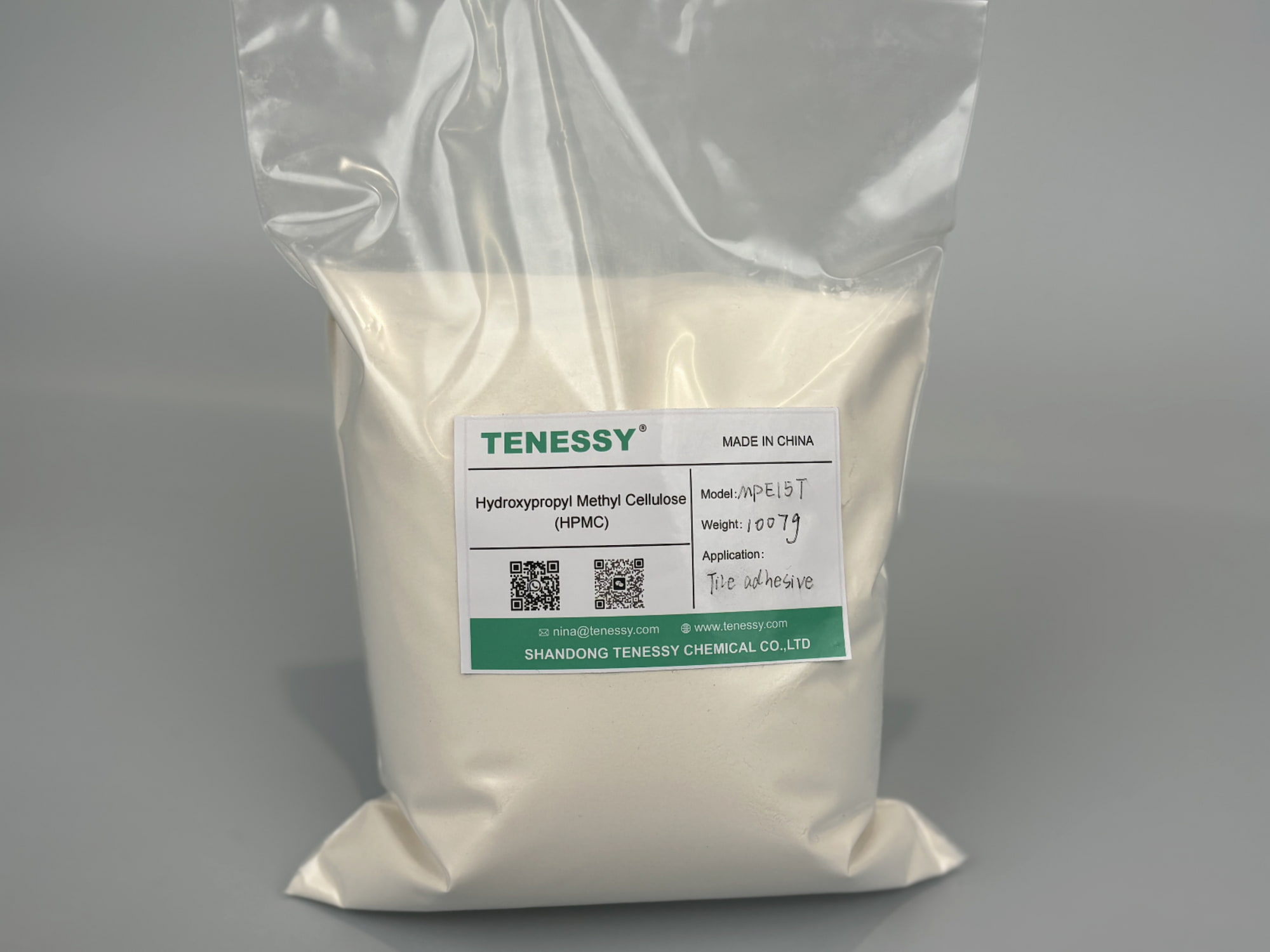

Packaging & Storage

- Packaging: 25 kg multi-layer kraft paper bag with PE inner liner.

- Pallet: 40 bags (1,000 kg) per pallet, securely stretch-wrapped.

- Storage: Store in a cool, dry place away from moisture and direct sunlight.

- Shelf Life: 24 months in unopened original packaging.

Free HPMC Sample

Experience how TENESSY HPMC improves your tile adhesive performance.

Request a free sample or contact our technical team for formulation guidance. We’ll help you develop tile adhesives with perfect workability, strong bonding, and long-lasting durability.

FAQ

HPMC controls water retention, improves workability, and increases bonding strength, ensuring reliable tile installation.