Top 5 Concrete Additives to Prevent Cracking in Real Projects

Top 5 Concrete Additives to Prevent Cracking in Real Projects Concrete is an essential material

We have advanced production equipment and use automated production lines to strictly control the viscosity and quality of cellulose ether.

We use high-grade refined cotton with stable molecular weight and low impurity content. The production process is fully traceable from raw materials to final products.

Advanced automation system, each key parameter can be monitored in real time to ensure stable product viscosity, uniform particle size and batch-to-batch consistency.

Our production lines are highly uniform in design and strictly control quality. We not only produce products, but also solve problems for customers, improve formulations, and meet local application standards.

Ensure that the samples you test are of the same quality as the bulk products.

With our own production factory, we can provide OEM services.

Founded In

Annual Output

Serving Customers

Exporting Countries

As a professional cellulose ether manufacturer, we have a complete product system, mainly focusing on the three major series of cellulose ethers: HPMC, HEMC, and HEC, with dozens of specifications of products. Of course, we can also customize products for you.

Stable thickening

Extended open time

Highly efficient water retention

Cold water soluble & easy to disperse

Excellent water retention

Highly efficient thickening

Strong resistance to enzymolysis

Stable high temperature resistance

Improves water retention

Stabilized and biodegradable

Non-gel and easy to dissolve

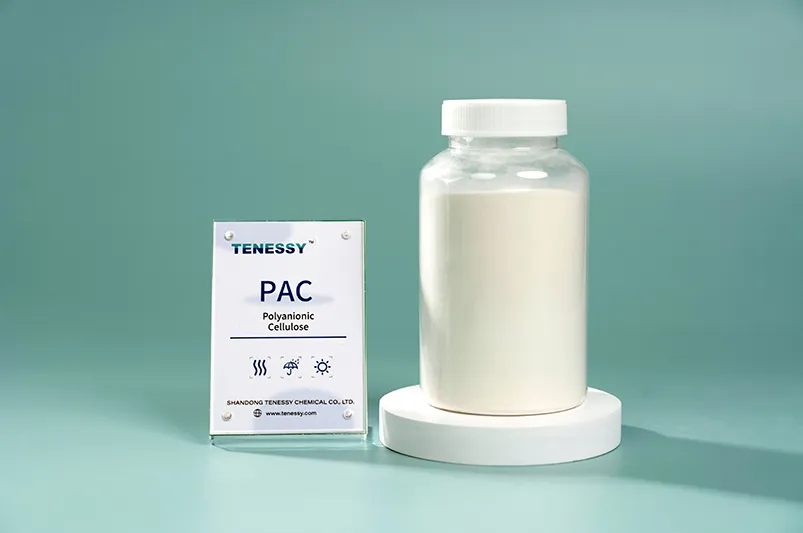

Excellent thickening and suspension

Dissolves Easily in Water

Effective Thickening

Excellent Water Retention

Strong Binding

High Stability

Improved Water Resistance

Higher Thickening Efficiency

Longer Open Time

Excellent Stability

Superior heat resistance

Improves water retention

Effective thickener

Reduces water loss

Our cellulose ethers are used in a variety of industries. According to your different application formulations, we will recommend the most suitable products and models, provide samples for you to test.

We select refined cotton as raw material and strictly control the quality of the raw materials at the source.

Intelligent control system effectively reduces human errors and improves production efficiency.

TENESSY ensures consistent quality, whether it is a 1 kg sample or a 100 ton order.

We provide customized formulation services in multiple dimensions such as viscosity and open time.

Crushing natural cellulose raw materials.

Reacts with sodium hydroxide to form alkali cellulose.

An etherifying agent is added to the alkali cellulose.

Adjust the pH of the reaction solution with acid

Remove impurities and increase purity in the washing tank.

Conveyed into the dryer and dried at 150 -170℃.

From formulation optimization to construction performance, our experienced R&D team is always available to provide you with tailored technical support and improvement suggestions.

Our cellulose ether products are widely used in many industries such as construction, coatings, daily chemicals, and pharmaceuticals, and their quality is recognized by customers everywhere.

We have a professional international sales team and technical solution support to continuously assist you in using products, application improvements and formula upgrades. We focus on customized services and long-term cooperation, while ensuring a stable supply of products, and hope to make progress with you.

Got questions? Here are the answers our customers ask most.

Blandit tortor Platea quam dictum senectus proin quis。坐智人 facilisis ullamcorper vulputate。 Dapibus volutpat curae pharetra porta mattis magnis facilisi Massa Phasellus etiam nullam。

Blandit tortor Platea quam dictum senectus proin quis。坐智人 facilisis ullamcorper vulputate。 Dapibus volutpat curae pharetra porta mattis magnis facilisi Massa Phasellus etiam nullam。

Blandit tortor Platea quam dictum senectus proin quis。坐智人 facilisis ullamcorper vulputate。 Dapibus volutpat curae pharetra porta mattis magnis facilisi Massa Phasellus etiam nullam。

Blandit tortor Platea quam dictum senectus proin quis。坐智人 facilisis ullamcorper vulputate。 Dapibus volutpat curae pharetra porta mattis magnis facilisi Massa Phasellus etiam nullam。

Blandit tortor Platea quam dictum senectus proin quis。坐智人 facilisis ullamcorper vulputate。 Dapibus volutpat curae pharetra porta mattis magnis facilisi Massa Phasellus etiam nullam。

Blandit tortor platea quam dictum senectus proin quis. Sit sapien mauris facilisis ullamcorper vulputate. Dapibus volutpat curae pharetra porta mattis magnis facilisi massa phasellus etiam nullam.

Blandit tortor platea quam dictum senectus proin quis. Sit sapien mauris facilisis ullamcorper vulputate. Dapibus volutpat curae pharetra porta mattis magnis facilisi massa phasellus etiam nullam.

Blandit tortor platea quam dictum senectus proin quis. Sit sapien mauris facilisis ullamcorper vulputate. Dapibus volutpat curae pharetra porta mattis magnis facilisi massa phasellus etiam nullam.

Blandit tortor platea quam dictum senectus proin quis. Sit sapien mauris facilisis ullamcorper vulputate. Dapibus volutpat curae pharetra porta mattis magnis facilisi massa phasellus etiam nullam.

Blandit tortor platea quam dictum senectus proin quis. Sit sapien mauris facilisis ullamcorper vulputate. Dapibus volutpat curae pharetra porta mattis magnis facilisi massa phasellus etiam nullam.

Top 5 Concrete Additives to Prevent Cracking in Real Projects Concrete is an essential material

The Addition of Tenessy CMC: Enhancing Paper Quality and Achieving Energy Savings & Environmental Protection

What Is Methyl Hydroxyethyl Cellulose (MHEC) Used for? Methyl Hydroxyethyl Cellulose, usually called MHEC, is

TENESSY has more than 10 years of production experience and advanced production equipment.

Fill in to get a free sample or consult for more information.