Self Leveling

self leveling additives

Self Leveling Mortar

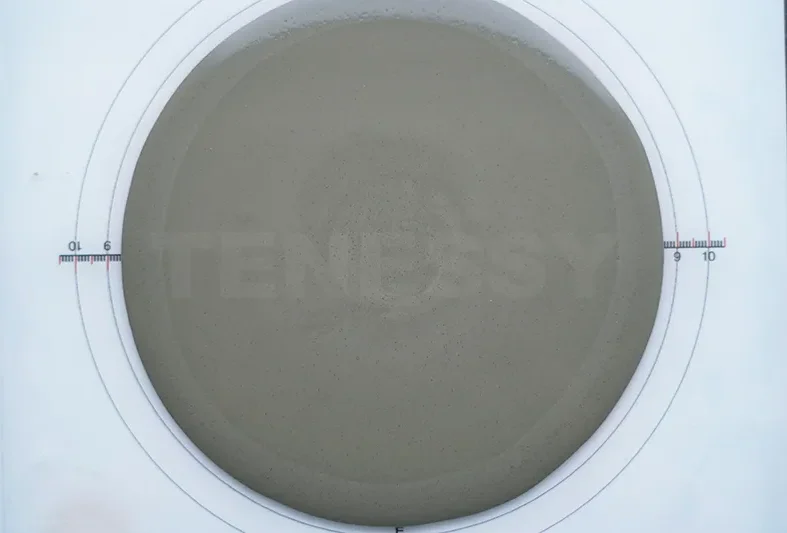

Self leveling mortar is an easy-flowing, high-performance flooring material used to create a smooth, flat, durable surface.

It is often used as a self leveling underlayment for tiles, wood floors, vinyl, and more, or even as a finished surface using self-leveling cement.

Reliable Self Leveling Mortar Performance with High-Quality Additives

Whether used as self leveling underlayment or as a finished self-leveling cement floor, the quality of your formula determines flow, strength, and final surface results.

At TENESSY, we offer tailor-made self levelling additives (HPMC, RDP, PCE, Powder Defoamer) that improve flow, prevent cracking and ensure your self levelling mortar achieves the surface finish your customers expect.

Whether you produce gypsum-based or cement-based self leveling mortars, additives are the key to staying competitive.

Recommend Self Leveling Additives

Tenessy provides various grades and performances of self leveling to meet all customers’ needs.

Hydroxypropyl Methyl Cellulose 400Mpa.s

Improves water retention, workability, and surface smoothness, essential for crack resistance.

Redispersible Polymer Powder

Enhances flexibility, adhesion, and impact resistance, especially for thin-layer applications.

Polycarboxylate Superplasticizer

Increases flow and spreadability without adding extra water, ideal for self leveling underlayment.

Common Problems in Self Leveling Applications

Rapid water loss causing cracks and reduced strength

Surface defects like pinholes, shrinkage cracks, or dusting

Weak adhesion to the base substrate

Poor leveling due to insufficient flow or segregation

TENESSY provides a full range of self leveling additives to help you overcome these problems efficiently.

Using TENESSY Self Leveling Additives

Using premium-grade additives like HPMC, RDP, PCE powder, and others can significantly improve the performance and stability of your self leveling products. Here’s how they help:

- Enhance pumpability and spread in large areas.

- Control shrinkage during drying and curing.

- Boost adhesion to various substrates (concrete, screeds, existing floors).

- Eliminates air bubbles and pinholes, reduced surface defects.

Technical Support

Advanced Technical Support from TENESSY

We understand that every formulation is unique. That’s why our team works closely with customers to:

Recommend ideal dosage levels

Adjust binder-to-additive ratios

Conduct lab testing for performance validation

Support pilot batch production

other industry

More Application

Tile Adhesive

Drymix Mortar

Gypsum Based Plaster

Wall Putty

EIFS

Try Our FREE Products Sample!Customized self-leveling formulations based on your needs.

Self Leveling Additives from TENESSY Manufacturer

At Tenessy, experience our products firsthand with a FREE sample!

– Sample Size: 200g or 400g.

– Shipping: Fast via FedEx or DHL.

– Service: Expert formula adjustment support.

FAQ

It depends on your base binder (cement or gypsum), layer thickness, flow requirements, and working time. Our technical team can help you formulate based on your local raw materials.

Underlayment is typically thicker and designed to be covered by flooring, while topcoats require higher abrasion resistance and finish. We offer additive packages suitable for both.

Use RDP and HPMC together to improve elasticity and water retention. PCE also helps to reduce the water-to-cement ratio, which lowers shrinkage.