HPS for Wall Putty

Tenessy HPS for Wall Putty

Hydroxypropyl Starch Ether (HPS) is a high-performance additive widely used in cement-based and gypsum-based wall putty formulations. Derived from natural starch and modified through etherification, HPS provides excellent water retention, thickening, and workability enhancement.

In wall putty, HPS plays a critical role in improving application smoothness, open time, and overall consistency. It ensures that the putty spreads easily on walls, forms a strong bond with the substrate, and provides a smooth, even surface ready for painting or finishing.

How Does HPS Work in Wall Putty?

When added to wall putty formulations, HPS dissolves in water to form a stable, viscous solution

that interacts with cement particles and fillers. This reaction enhances the physical properties

of the putty in several ways:

- Improves water retention, preventing premature drying and enhancing adhesion to the wall.

- Increases viscosity and consistency, resulting in a smoother, creamier texture during application.

- Enhances workability, making it easier to spread and level without sagging or cracking.

- Extends open time, allowing applicators more flexibility and reducing waste.

Through these combined effects, HPS ensures a stable and easy-to-use wall putty

with superior surface quality.

Recommended HPS Products

HPS S600

High viscosity and improved workability, ideal for high-performance formulations.

Benefits of Using HPS in Wall Putty

- Excellent Workability – Provides a smooth, easy-to-spread texture for both hand and machine application.

- Enhanced Water Retention – Keeps the surface moist for proper curing, resulting in stronger adhesion and fewer cracks.

- Improved Consistency – Ensures a uniform mixture with excellent leveling and surface coverage.

- Longer Open Time – Gives applicators more time to adjust and finish the surface before hardening.

- Better Surface Finish – Produces a denser, smoother, and more paint-ready wall surface.

- Crack Resistance – Reduces surface shrinkage and prevents micro-cracking.

More Solutions and Applications

TENESSY™ HPS improves the workability, consistency, and adhesion of wall putty materials. It ensures smooth application and reliable performance in plasters, wall putty, joint fillers, and other gypsum products.

Partner with TENESSY — Your Trusted HPS Supplier

Why Choose TENSESSY™ HPS

- Consistent Product Quality: Tight viscosity control and batch stability ensure predictable performance.

- Tailored Solutions: Grades optimized for various cement-based and gypsum-based wall putty systems.

- Reliable Technical Support: Expert guidance for product formulation and on-site testing.

- Sustainable Production: Made from renewable plant-based starch, supporting green building initiatives.

- Global Supply Network: Stable production capacity and timely delivery for both domestic and export markets.

Request a Free Sample

We offer free HPS samples for formulation testing and product evaluation. Contact Tenessy to request your sample and discover how HPS can elevate your wall putty’s performance and finish quality.

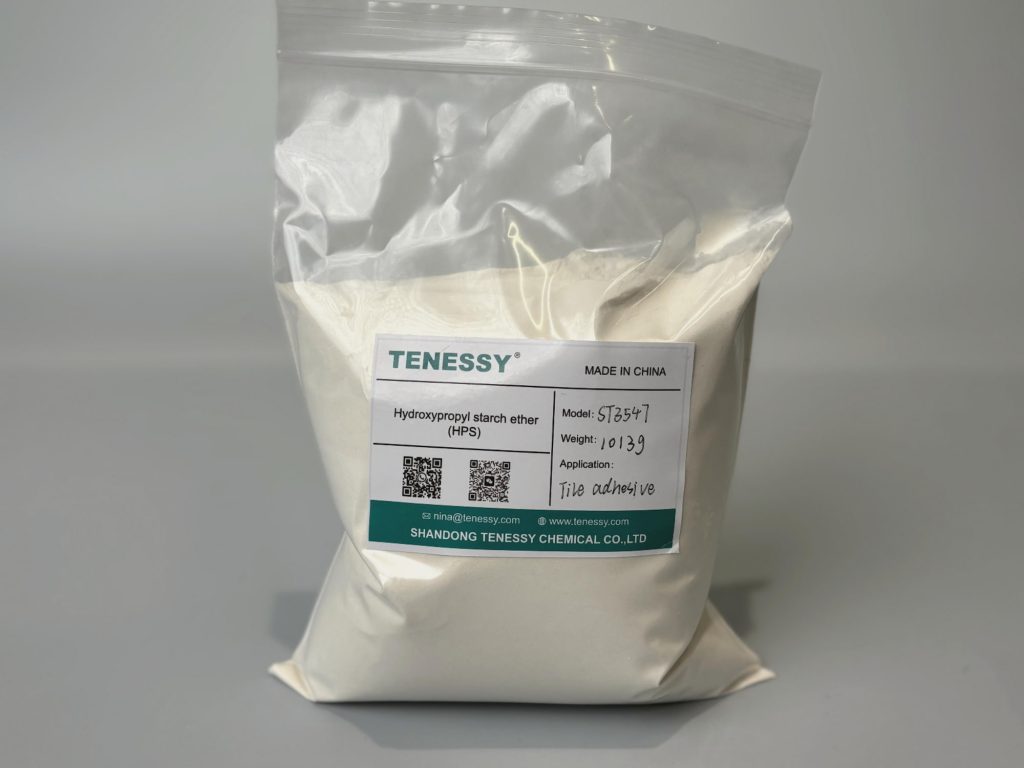

Packaging & Storage

> Packaging: 25kg paper or PP woven bags with moisture-proof inner lining.

> Storage: Store in a cool, dry, ventilated area, away from moisture and direct sunlight.

> Shelf Life: 12 months in unopened packaging. Once opened, reseal properly to prevent moisture absorption.

Frequently Asked Questions