Carboxymethyl Cellulose (CMC)

TENESSY - Uma empresa confiável CMC Manufacturer in China

CMC (Carboxymethyl Cellulose) is a water-soluble material made from natural plant fibers such as cotton or wood pulp through a modification process. It works well as a thickener, water retainer, suspending agent, and binder.

CMC has a wide range of uses — mainly serving as a thickener, stabilizer, water-retaining agent, and film-forming agent. It is commonly used in food, pharmaceuticals, detergents, ceramics, papermaking, textiles, and drilling fluids industries.

Technical Properties

*The performance of CMC is determined by two key parameters: its degree of substitution (DS) and viscosity. Products with different values are suited for different applications.

| Key Parameter | Definition & Effect | Typical Range |

| Degree of Substitution (DS) | Number of hydroxyl groups in each cellulose unit replaced by carboxymethyl (-CH₂COOH). This affects CMC’s water solubility and chemical activity. | 0.4–1.5 (Industrial: 0.7–1.2; Food grade: ≥0.9 for full solubility) |

| Viscosity | Measures how thick a CMC solution is. Related to molecular chain length. Usually measured with a 2% solution at 25°C. | 50–100,000 mPa·s (Low viscosity 50–500 for clear liquids; High viscosity 5,000–100,000 for thickening or shaping) |

Key Features of Carboxymethyl Cellulose (CMC)

- Dissolves Easily in Water: When its DS value is ≥0.7, CMC quickly dissolves in cold/hot water, forming a clear, smooth solution without any sediment.

- Effective Thickening & Suspending: Low doses (0.5%-2%) boost viscosity and suspend particles (e.g., fruit in food, pigments in paints), preventing settling.

- Excellent Water Retention: The hydroxyl (-OH) and carboxyl (-COOH) groups in CMC molecules bond with water, minimizing evaporation/leakage. This is especially useful in construction materials.

- Strong Binding: CMC’s sticky solution can hold scattered particles—like gypsum, cement, or powdered food—together, making products stronger and better shaped.

- High Stability: Acid/alkali resistant (stable pH 2-10; degrades in extremes), salt-tolerant at low levels (may precipitate in high salt), and microbe-resistant (add preservatives for long storage).

Solicite seu Free CMC Sample Hoje!

Reach out to us, and our team will create a sample designed specifically for your requirements. Whether it’s for lab testing or a full-scale project, we’re ready to assist you.

We can also supply comprehensive technical datasheets and professional guidance to ensure you have all the information needed to make the right choice.

Main Aplicativos of Carboxymethyl Cellulose in Various Industries

Carboxymethyl Cellulose (CMC) is a versatile, water-soluble polymer widely used across multiple industries. Its unique properties—such as thickening, stabilizing, water retention, and binding—make it an essential ingredient in food, paper, textiles, detergents, coatings, and other industrial applications. Depending on the grade and formulation, CMC helps improve product performance, processing efficiency, and overall quality.

CMC in Oil Drilling

CMC is used in drilling, cementing, and fracturing fluids to control fluid loss and increase viscosity. It helps protect the borehole wall, carry drill cuttings, protect the drill bit, prevent mud loss, and improve drilling efficiency.

It can be added directly to the mud or mixed into a gel before use. The typical dosage is 0.1%–0.3% in fresh water slurry and 0.5%–0.8% in salt water slurry.

| Model | Viscometer Reading at 600 r/min | Fluid Loss (mL) | ||

|---|---|---|---|---|

| Deionized Water | 40 g/L Salt Water | Saturated Salt Water | ||

| LV-CMC | ≤ 90 | ≤ 10 | ||

| HV-CMC | ≥ 30 | ≥ 30 | ≥ 30 | ≤ 10 |

| Model | Apparent Viscosity (mPa.s) | Fluid Loss (mL) | Dry Weight Loss (%) | Degree of Substitution (D.S) |

|---|---|---|---|---|

| PAC-LV | ≤ 40 | ≤ 16 | ≤ 10 | ≥ 0.9 |

| PAC-HV | ≥ 50 | ≤ 16 | ≤ 10 | ≥ 0.9 |

CMC in Food

CMC is widely used in the food industry. It acts as a thickener, stabilizer, and texture improver in dairy drinks and sauces. In products like ice cream, bread, pastries, instant noodles, and ready-to-eat porridges, it helps with shaping, improving texture, retaining water, and enhancing elasticity. The recommended addition amount is generally 0.3–1.0%.

Technical Specifications of Food-Grade CMC

| Grau | Degree of Substitution | Viscosity | Purity | pH | Moisture |

|---|---|---|---|---|---|

| F20 | 0.7-0.95 | 2% 25-50 | ≥98 | 6.5-8.5 | ≤10 |

| F80 | 0.7-0.95 | 1% 80-120 | ≥99.5 | 6.5-8.5 | ≤10 |

| F100 | 0.7-0.95 | 1% 100-200 | ≥99.5 | 6.5-8.5 | ≤10 |

| F500 | 0.7-0.95 | 1% 400-600 | ≥99.5 | 6.5-8.5 | ≤10 |

| F700 | 0.7-0.9 | 1% 600-800 | ≥99.5 | 6.5-8.5 | ≤10 |

| F1000 | 0.7-0.9 | 1% 800-1200 | ≥99.5 | 6.5-8.5 | ≤10 |

| F2000 | 0.7-0.9 | 1% 2000-3000 | ≥99.5 | 6.5-8.5 | ≤10 |

| F3000 | 0.7-0.9 | 1% 3000-4000 | ≥99.5 | 6.5-8.5 | ≤10 |

| F4000 | 0.7-0.9 | 1% 4000-5000 | ≥99.5 | 6.5-8.5 | ≤10 |

| F5000 | 0.7-0.9 | 1% 5000-6000 | ≥99.5 | 6.5-8.5 | ≤10 |

| F6000 | 0.7-0.9 | 6000 min | ≥99.5 | 6.5-8.5 | ≤10 |

- Purity: Standard grade ≥98.0%; high grade ≥99.5%; ultra-high purity requires “H” before the product code.

- Viscosity: Measurements differ depending on the type of viscometer used. Viscosity is selected based on customer requirements.

CMC in Personal Care

CMC is widely used in personal care products. It helps keep ingredients evenly mixed, prevents particles from settling again, retains moisture, and provides stability and thickening. It dissolves quickly and is easy to use. The typical dosage is 0.3%–1.0%.

In toothpaste, CMC works as a binder and thickener. It gives the toothpaste its shape, helps it stay smooth and uniform, and prevents water from separating from the paste. The recommended dosage is 0.5%–1.5%.

Technical Specifications of Personal Care Grade CMC

| Grau | Degree of Substitution | Viscosity | Purity | pH | Moisture |

|---|---|---|---|---|---|

| TC200 | ≥0.95 | 1% 200-400 | ≥98 | 6.5-8.5 | ≤10 |

| TC300 | ≥1.0 | 1% 200-400 | ≥98 | 6.5-8.5 | ≤10 |

| TC600 | ≥0.70 | 1% 400-700 | ≥99.5 | 6.5-8.5 | ≤10 |

| TC2000 | ≥0.80 | 1% 2000-2500 | ≥98 | 6.5-8.5 | ≤10 |

| TC1000 | ≥0.90 | 1% 800-1200 | ≥98 | 6.5-8.5 | ≤10 |

CMC in Paper

In the papermaking process, CMC helps the pulp stay on the paper mesh better and increases the wet strength of the paper. When used for surface sizing, it helps pigments stick firmly to the paper, reduces dust during printing, and improves print quality. In paper coating, it helps pigments spread evenly, making the paper smoother, glossier, and more suitable for printing. The typical recommended dosage is 0.3%–1.5%.

Technical Specifications of Paper-Grade CMC

| Grau | Degree of Substitution | Viscosity | Purity | pH | Moisture |

|---|---|---|---|---|---|

| P15 | ≥0.80 | 1% 5-20 | ≥95 | 6.5-8.5 | ≤10 |

| P35 | ≥0.80 | 1% 20-50 | ≥95 | 6.5-8.5 | ≤10 |

| P150 | ≥0.80 | 1% 50-200 | ≥90 | 6.5-8.5 | ≤10 |

| P500 | ≥0.80 | 1% 300-800 | ≥90 | 6.5-8.5 | ≤10 |

| P1000 | ≥0.80 | 1% 800-1200 | ≥90 | 6.5-8.5 | ≤10 |

CMC in Detergents

In detergents, CMC plays several key roles. It helps keep dirt suspended in water to prevent redeposition onto fabrics, maintains moisture, provides stabilization and thickening, and improves overall cleaning performance. It also dissolves easily, making it convenient to use.

Technical Specifications of Detergent-Grade CMC:

| Grau | Degree of Substitution | Viscosity | Purity | pH | Moisture |

|---|---|---|---|---|---|

| W2000 | ≥0.80 | 1% ≥2000 | ≥90 | 6.5-8.5 | ≤10 |

| W3000 | ≥0.80 | 1% ≥3000 | ≥90 | 6.5-8.5 | ≤10 |

| W4000 | ≥0.90 | 1% ≥4000 | ≥90 | 6.5-8.5 | ≤10 |

| W6000 | ≥0.70 | 1% ≥6000 | ≥95 | 6.5-8.5 | ≤10 |

| W3000C | ≥0.90 | 1% ≥3000 | ≥90 | 6.5-8.5 | ≤10 |

| W5000C | ≥0.70 | 1% ≥5000 | ≥95 | 6.5-8.5 | ≤10 |

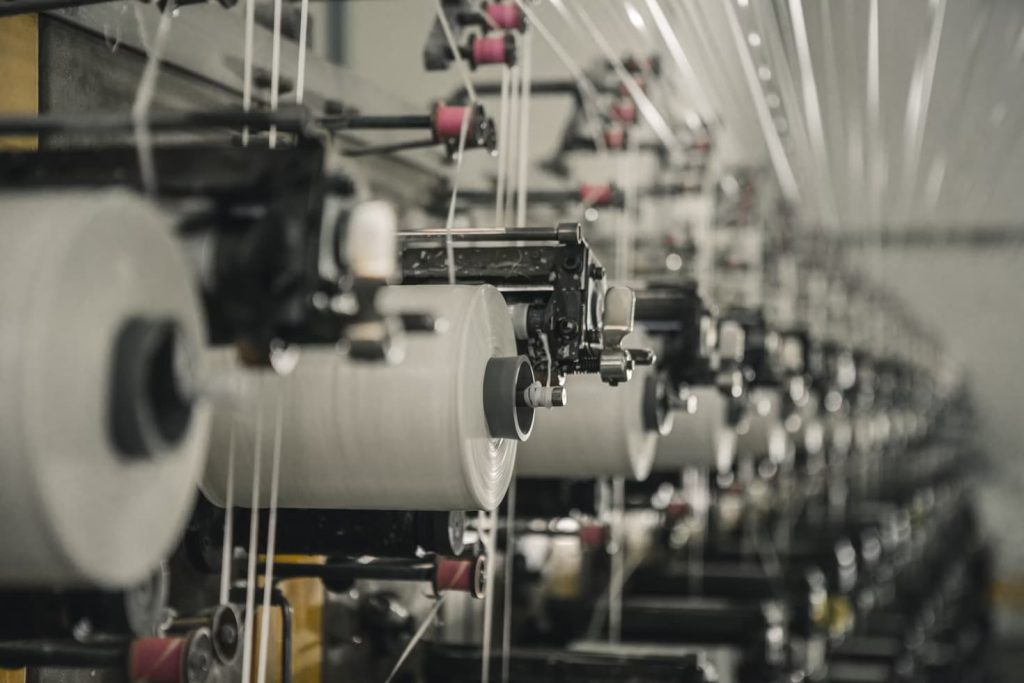

CMC in Textile Printing and Dyeing

CMC is widely used in the textile industry to improve product quality and processing efficiency:

- In spinning, it helps reduce yarn breakage, increase production rates, and improve yarn strength. The recommended dosage is 0.3%–1.5%.

- In dyeing and printing, CMC acts as a suspension agent for dyes, improves color adhesion, ensures uniform printing, and enhances print clarity. The recommended dosage is 0.5%–2.0%.

Technical Specifications of Textile and Dyeing Grade CMC:

| Grau | Degree of Substitution | Viscosity | Purity | pH | Moisture |

|---|---|---|---|---|---|

| T1600 | ≥1.05 | 1% 1500-1800 | ≥95 | 6.5-8.5 | ≤10 |

| T1100 | ≥1.15 | 1% 1000-1200 | ≥90 | 6.5-8.5 | ≤10 |

| T1600 | ≥1.20 | 1% 1500-1800 | ≥90 | 6.5-8.5 | ≤10 |

| T600 | ≥1.30 | 1% 500-700 | ≥90 | 6.5-8.5 | ≤10 |

| PAC-2000 | ≥1.0 | 1% 2200-2500 | ≥95 | 6.5-8.5 | ≤10 |

| PAC-LV | ≥1.0 | 1% 50-80 | ≥95 | 6.5-8.5 | ≤10 |

Other Industrial-Grade CMC Applications

CMC is used in various industrial fields such as coatings, mosquito coils, welding rods, batteries, and detergents. It acts as a retarder, water retention agent, thickener, and binder to improve product performance and processing quality.

| Grau | Degree of Substitution | Viscosity | Purity | pH | Moisture |

|---|---|---|---|---|---|

| CMT200 | ≥0.70 | 1% 100-300 | ≥70 | 6.0-9.0 | ≤10 |

| CMT800 | ≥0.65 | 1% 800-1200 | ≥80 | 6.0-9.0 | ≤10 |

| CMT900 | ≥0.85 | 1% 800-1200 | ≥98 | 6.5-8.5 | ≤10 |

| CMT1000 | ≥0.90 | 1% 800-1200 | ≥99.5 | 6.5-8.5 | ≤10 |

| CMT1200 | ≥0.75 | 1% 800-1200 | ≥80 | 6.0-9.0 | ≤10 |

O que a Tenessy oferece

Reliable Quality and Advanced Production

TENESSY™ CMC is produced from high-purity cellulose using cutting-edge technology and rigorous quality management. Each batch delivers consistent viscosity, minimal filtration loss, and outstanding performance under challenging conditions.

we provide the best quality

CMC Packaging & Sizes

25kg Bag

TENESSY™ CMC is supplied in durable polypropylene woven bags lined with polyethylene for added protection. Each bag holds 25 kg, making storage and handling simple and safe.

600kg Pallet

For bulk purchases, CMC can be delivered on 600 kg pallets, with customizable packaging options available to suit your project needs.

Customized Packaging

Perguntas frequentes

Carboxymethyl Cellulose (CMC) is a versatile compound used as a thickener, stabilizer, and binder in various industries. It is commonly found in food products, pharmaceuticals, personal care items, and industrial applications such as drilling fluids and construction materials.