Carboximetilcelulose (CMC)

TENESSY - Uma empresa confiável CMC Fabricante na China

A CMC (Carboximetilcelulose) é um material solúvel em água feito de fibras vegetais naturais, como algodão ou polpa de madeira, por meio de um processo de modificação. Ele funciona bem como espessante, retentor de água, agente de suspensão e aglutinante.

A CMC tem uma ampla gama de usos, principalmente como espessante, estabilizador, agente de retenção de água e agente formador de filme. É comumente usado em alimentos, produtos farmacêuticos, detergentes, cerâmica, fabricação de papel, têxteis e fluidos de perfuração setores.

Propriedades técnicas

*O desempenho da CMC é determinado por dois parâmetros principais: o grau de substituição (DS) e a viscosidade. Produtos com valores diferentes são adequados para diferentes aplicações.

| Parâmetro-chave | Definição e efeito | Faixa típica |

| Grau de substituição (DS) | Número de grupos hidroxila em cada unidade de celulose substituídos por carboximetil (-CH₂COOH). Isso afeta a solubilidade em água e a atividade química da CMC. | 0,4-1,5 (industrial: 0,7-1,2; grau alimentício: ≥0,9 para solubilidade total) |

| Viscosidade | Mede a espessura de uma solução de CMC. Relacionado ao comprimento da cadeia molecular. Geralmente medido com uma solução 2% a 25°C. | 50-100.000 mPa-s (baixa viscosidade 50-500 para líquidos transparentes; alta viscosidade 5.000-100.000 para espessamento ou modelagem) |

Principais recursos de Carboximetilcelulose (CMC)

- Dissolve-se facilmente em água: Quando seu valor DS é ≥0.7, A CMC se dissolve rapidamente em água fria/quente, formando uma solução límpida e suave, sem nenhum sedimento.

- Espessamento e suspensão eficazes: Doses baixas (0,5%-2%) aumentam a viscosidade e suspendem as partículas (por exemplo, frutas em alimentos, pigmentos em tintas), evitando a sedimentação.

- Excelente retenção de água: Os grupos hidroxila (-OH) e carboxila (-COOH) nas moléculas de CMC se ligam à água, minimizando a evaporação/vazamento. Isso é especialmente útil em materiais de construção.

- Encadernação forte: A solução pegajosa da CMC pode manter juntas as partículas dispersas, como gesso, cimento ou alimentos em pó, tornando os produtos mais fortes e com melhor formato.

- Alta estabilidade: Resistente a ácidos/álcalis (pH estável de 2 a 10; degrada-se em extremos), tolerante ao sal em níveis baixos (pode precipitar em sal alto) e resistente a micróbios (adicione conservantes para armazenamento prolongado).

Solicite seu Amostra grátis de CMC Hoje!

Entre em contato conosco e nossa equipe criará uma amostra projetada especificamente para as suas necessidades. Seja para testes de laboratório ou para um projeto em grande escala, estamos prontos para ajudá-lo.

Também podemos fornecer planilhas de dados técnicos abrangentes e orientação profissional para garantir que você tenha todas as informações necessárias para fazer a escolha certa.

Principal Aplicativos de Carboximetilcelulose em vários setores

A carboximetilcelulose (CMC) é um polímero versátil e solúvel em água amplamente utilizado em vários setores. Suas propriedades exclusivas, como espessamento, estabilização, retenção de água e ligação, fazem dele um ingrediente essencial em alimentos, papel, têxteis, detergentes, revestimentos e outras aplicações industriais. Dependendo do grau e da formulação, a CMC ajuda a melhorar o desempenho do produto, a eficiência do processamento e a qualidade geral.

CMC na perfuração de petróleo

A CMC é usada em perfuração, cimentação e fluidos de fraturamento para controle fluido perda e aumento viscosidade. Isso ajuda protegem a parede do furo, transportam os detritos de perfuração, protegem a broca, evitam a perda de lama e melhoram a eficiência da perfuração.

Ele pode ser adicionado diretamente à lama ou misturado em um gel antes do uso. A dosagem típica é 0,1%-0,3% em pasta de água doce e 0,5%-0,8% em pasta de água salgada.

| Modelo | Leitura do viscosímetro a 600 r/min | Perda de fluido (mL) | ||

|---|---|---|---|---|

| Água deionizada | 40 g/L Água salgada | Água salgada saturada | ||

| LV-CMC | ≤ 90 | ≤ 10 | ||

| HV-CMC | ≥ 30 | ≥ 30 | ≥ 30 | ≤ 10 |

| Modelo | Viscosidade aparente (mPa.s) | Perda de fluido (mL) | Perda de peso seco (%) | Grau de substituição (D.S) |

|---|---|---|---|---|

| PAC-LV | ≤ 40 | ≤ 16 | ≤ 10 | ≥ 0.9 |

| PAC-HV | ≥ 50 | ≤ 16 | ≤ 10 | ≥ 0.9 |

CMC em alimentos

A CMC é amplamente utilizada na indústria alimentícia. Ele atua como um espessante, estabilizador, e textura em bebidas lácteas e molhos. Em produtos como sorvete, pães, bolos, macarrão instantâneo e mingaus prontos para o consumo, ele ajuda a dar forma, melhorar a textura, reter água e aumentar a elasticidade. O quantidade de adição recomendada é geralmente 0,3-1,0%.

Especificações técnicas da CMC de grau alimentício

| Grau | Grau de substituição | Viscosidade | Pureza | pH | Umidade |

|---|---|---|---|---|---|

| F20 | 0.7-0.95 | 2% 25-50 | ≥98 | 6.5-8.5 | ≤10 |

| F80 | 0.7-0.95 | 1% 80-120 | ≥99.5 | 6.5-8.5 | ≤10 |

| F100 | 0.7-0.95 | 1% 100-200 | ≥99.5 | 6.5-8.5 | ≤10 |

| F500 | 0.7-0.95 | 1% 400-600 | ≥99.5 | 6.5-8.5 | ≤10 |

| F700 | 0.7-0.9 | 1% 600-800 | ≥99.5 | 6.5-8.5 | ≤10 |

| F1000 | 0.7-0.9 | 1% 800-1200 | ≥99.5 | 6.5-8.5 | ≤10 |

| F2000 | 0.7-0.9 | 1% 2000-3000 | ≥99.5 | 6.5-8.5 | ≤10 |

| F3000 | 0.7-0.9 | 1% 3000-4000 | ≥99.5 | 6.5-8.5 | ≤10 |

| F4000 | 0.7-0.9 | 1% 4000-5000 | ≥99.5 | 6.5-8.5 | ≤10 |

| F5000 | 0.7-0.9 | 1% 5000-6000 | ≥99.5 | 6.5-8.5 | ≤10 |

| F6000 | 0.7-0.9 | 6000 min | ≥99.5 | 6.5-8.5 | ≤10 |

- Pureza: Grau padrão ≥98,0%; alto grau ≥99,5%; ultra-alta pureza requer “H” antes do código do produto.

- Viscosidade: As medições variam de acordo com o tipo de viscosímetro utilizado. A viscosidade é selecionada com base nos requisitos do cliente.

CMC em cuidados pessoais

A CMC é amplamente utilizada em produtos para cuidados pessoais. Ajuda a manter os ingredientes uniformemente misturados, evita que as partículas se depositem novamente, retém a umidade e proporciona estabilidade e espessamento. Dissolve-se rapidamente e é fácil de usar. A dosagem típica é 0,3%-1,0%.

Em pasta de dente, A CMC funciona como um aglutinante e espessante. Ele dá à pasta de dente seu formato, ajuda a mantê-la lisa e uniforme e evita que a água se separe da pasta. A dosagem recomendada é 0,5%-1,5%.

Especificações técnicas da CMC para cuidados pessoais

| Grau | Grau de substituição | Viscosidade | Pureza | pH | Umidade |

|---|---|---|---|---|---|

| TC200 | ≥0.95 | 1% 200-400 | ≥98 | 6.5-8.5 | ≤10 |

| TC300 | ≥1.0 | 1% 200-400 | ≥98 | 6.5-8.5 | ≤10 |

| TC600 | ≥0.70 | 1% 400-700 | ≥99.5 | 6.5-8.5 | ≤10 |

| TC2000 | ≥0.80 | 1% 2000-2500 | ≥98 | 6.5-8.5 | ≤10 |

| TC1000 | ≥0.90 | 1% 800-1200 | ≥98 | 6.5-8.5 | ≤10 |

CMC em papel

No processo de fabricação de papel, o CMC ajuda a polpa a se manter melhor na malha de papel e aumenta a resistência à umidade do papel. Quando usado para dimensionamento de superfície, O papel é um material de alta qualidade, que ajuda os pigmentos a aderirem firmemente ao papel, reduz a poeira durante a impressão e melhora a qualidade da impressão. Em revestimento de papel, O papel é um material de alta qualidade, que ajuda os pigmentos a se espalharem uniformemente, tornando o papel mais suave, mais brilhante e mais adequado para impressão. A dosagem típica recomendada é 0,3%-1,5%.

Especificações técnicas do CMC para papel

| Grau | Grau de substituição | Viscosidade | Pureza | pH | Umidade |

|---|---|---|---|---|---|

| P15 | ≥0.80 | 1% 5-20 | ≥95 | 6.5-8.5 | ≤10 |

| P35 | ≥0.80 | 1% 20-50 | ≥95 | 6.5-8.5 | ≤10 |

| P150 | ≥0.80 | 1% 50-200 | ≥90 | 6.5-8.5 | ≤10 |

| P500 | ≥0.80 | 1% 300-800 | ≥90 | 6.5-8.5 | ≤10 |

| P1000 | ≥0.80 | 1% 800-1200 | ≥90 | 6.5-8.5 | ≤10 |

CMC em detergentes

Nos detergentes, a CMC desempenha várias funções importantes. Ele ajuda a manter a sujeira suspensa na água para evitar a redeposição nos tecidos, mantém a umidade, proporciona estabilização e espessamento e melhora o desempenho geral da limpeza. Também se dissolve facilmente, o que torna seu uso conveniente.

Especificações técnicas da CMC com grau de detergente:

| Grau | Grau de substituição | Viscosidade | Pureza | pH | Umidade |

|---|---|---|---|---|---|

| W2000 | ≥0.80 | 1% ≥2000 | ≥90 | 6.5-8.5 | ≤10 |

| W3000 | ≥0.80 | 1% ≥3000 | ≥90 | 6.5-8.5 | ≤10 |

| W4000 | ≥0.90 | 1% ≥4000 | ≥90 | 6.5-8.5 | ≤10 |

| W6000 | ≥0.70 | 1% ≥6000 | ≥95 | 6.5-8.5 | ≤10 |

| W3000C | ≥0.90 | 1% ≥3000 | ≥90 | 6.5-8.5 | ≤10 |

| W5000C | ≥0.70 | 1% ≥5000 | ≥95 | 6.5-8.5 | ≤10 |

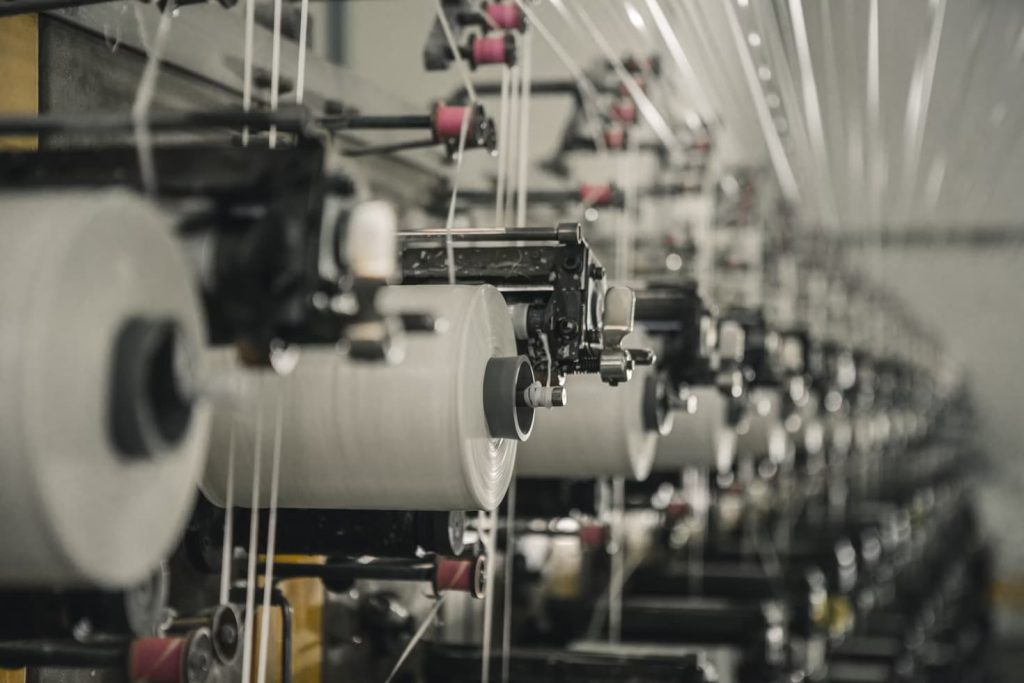

CMC em impressão e tingimento de têxteis

A CMC é amplamente utilizada na indústria têxtil para melhorar a qualidade do produto e a eficiência do processamento:

- Em fiação, O produto ajuda a reduzir a quebra do fio, aumentar as taxas de produção e melhorar a resistência do fio. A dosagem recomendada é 0,3%-1,5%.

- Em tingimento e impressão, A CMC atua como um agente de suspensão para corantes, melhora a adesão da cor, garante uma impressão uniforme e aumenta a clareza da impressão. A dosagem recomendada é 0,5%-2,0%.

Especificações técnicas da CMC de grau têxtil e de tingimento:

| Grau | Grau de substituição | Viscosidade | Pureza | pH | Umidade |

|---|---|---|---|---|---|

| T1600 | ≥1.05 | 1% 1500-1800 | ≥95 | 6.5-8.5 | ≤10 |

| T1100 | ≥1.15 | 1% 1000-1200 | ≥90 | 6.5-8.5 | ≤10 |

| T1600 | ≥1.20 | 1% 1500-1800 | ≥90 | 6.5-8.5 | ≤10 |

| T600 | ≥1.30 | 1% 500-700 | ≥90 | 6.5-8.5 | ≤10 |

| PAC-2000 | ≥1.0 | 1% 2200-2500 | ≥95 | 6.5-8.5 | ≤10 |

| PAC-LV | ≥1.0 | 1% 50-80 | ≥95 | 6.5-8.5 | ≤10 |

Outras aplicações de CMC de nível industrial

A CMC é usada em vários campos industriais, como revestimentos, bobinas de mosquito, hastes de solda, baterias e detergentes. Ele atua como retardador, agente de retenção de água, espessante e aglutinante para melhorar o desempenho do produto e a qualidade do processamento.

| Grau | Grau de substituição | Viscosidade | Pureza | pH | Umidade |

|---|---|---|---|---|---|

| CMT200 | ≥0.70 | 1% 100-300 | ≥70 | 6.0-9.0 | ≤10 |

| CMT800 | ≥0.65 | 1% 800-1200 | ≥80 | 6.0-9.0 | ≤10 |

| CMT900 | ≥0.85 | 1% 800-1200 | ≥98 | 6.5-8.5 | ≤10 |

| CMT1000 | ≥0.90 | 1% 800-1200 | ≥99.5 | 6.5-8.5 | ≤10 |

| CMT1200 | ≥0.75 | 1% 800-1200 | ≥80 | 6.0-9.0 | ≤10 |

O que a Tenessy oferece

Qualidade confiável e produção avançada

O TENESSY™ CMC é produzido a partir de celulose de alta pureza usando tecnologia de ponta e rigoroso gerenciamento de qualidade. Cada lote oferece viscosidade consistente, perda mínima de filtração e desempenho excepcional em condições desafiadoras.

Fornecemos a melhor qualidade

Embalagens e tamanhos de CMC

Saco de 25 kg

O TENESSY™ CMC é fornecido em sacos de tecido de polipropileno duráveis, revestidos com polietileno para maior proteção. Cada saco contém 25 kg, O que torna o armazenamento e o manuseio simples e seguro.

Palete de 600 kg

Para compras em grandes quantidades, o CMC pode ser entregue em paletes de 600 kg, com opções de embalagem personalizáveis disponíveis para atender às necessidades de seu projeto.

Embalagem personalizada

Perguntas frequentes

A carboximetilcelulose (CMC) é um composto versátil usado como espessante, estabilizador e aglutinante em vários setores. É comumente encontrado em produtos alimentícios, farmacêuticos, itens de higiene pessoal e aplicações industriais, como fluidos de perfuração e materiais de construção.