HPMC para masilla de pared

Tenessy - Reliable HPMC Manufacturer in China

Tenessy HPMC for Wall Putty

TENESSY Hydroxypropyl Methylcellulose (HPMC) is a high-performance cellulose ether derived from natural cotton cellulose, specially developed to enhance the workability, adhesion, and water retention of cement- or gypsum-based wall putty.

As a key additive, TENESSY HPMC provides superior consistency, prevents cracking and powdering, and ensures a smooth, durable surface that is ready for painting or further finishing. With optimized viscosity control and formulation stability, it helps manufacturers produce high-quality wall putty that meets professional construction standards.

The Functions of HPMC in Wall Putty

Wall putty is applied to even out surface imperfections and provide a uniform base for paints and coatings. To achieve good application and finishing results, wall putty requires balanced water retention, adhesion, and smoothness — all of which depend on the quality of HPMC used.

-

Water Retention: Maintains moisture during curing, ensuring full cement hydration and strong bonding.

-

Workability: Improves smoothness and spreadability for easy application and leveling.Adhesion Enhancement: Strengthens bonding to cement or plaster substrates, preventing peeling and powdering.Crack Resistance: Improves flexibility, reducing shrinkage and cracking during drying.Consistency & Stability: Prevents segregation and ensures uniform texture throughout mixing and application.Surface Finish: Produces a dense, smooth surface ideal for painting.

Why Tile Adhesive Needs HPMC

Modern wall putty formulations aim for smooth texture, easy application, and long durability. Without HPMC, wall putty tends to dry too quickly, crack, and lose adhesion.

Without HPMC

- Poor workability and drag during application.

- Uneven water absorption and fast drying, leading to cracks.

- Weak adhesion and powdering on the surface.

With TENESSY HPMC

- Excellent water retention for consistent curing.

- Smooth, creamy texture with easy spreadability.

- Strong adhesion and resistance to surface defects.

- Crack-free, durable finish that enhances paint appearance.

Recommended HPMC Grades for Wall Putty

TENESSY™ HEMC is available in various viscosity grades to suit different wall putty formulations. Each grade offers excellent water retention, smooth workability, and strong adhesion—ensuring a uniform, durable, and easy-to-apply finish.

*Custom viscosity and formulation adjustments available upon request.

HPMC MPT40

Medium viscosity grade ensuring smooth workability and water retention in standard cement-based wall putty.

HPMC MPT60

Balanced grade providing better adhesion, leveling, and longer open time for high-quality putty formulations.

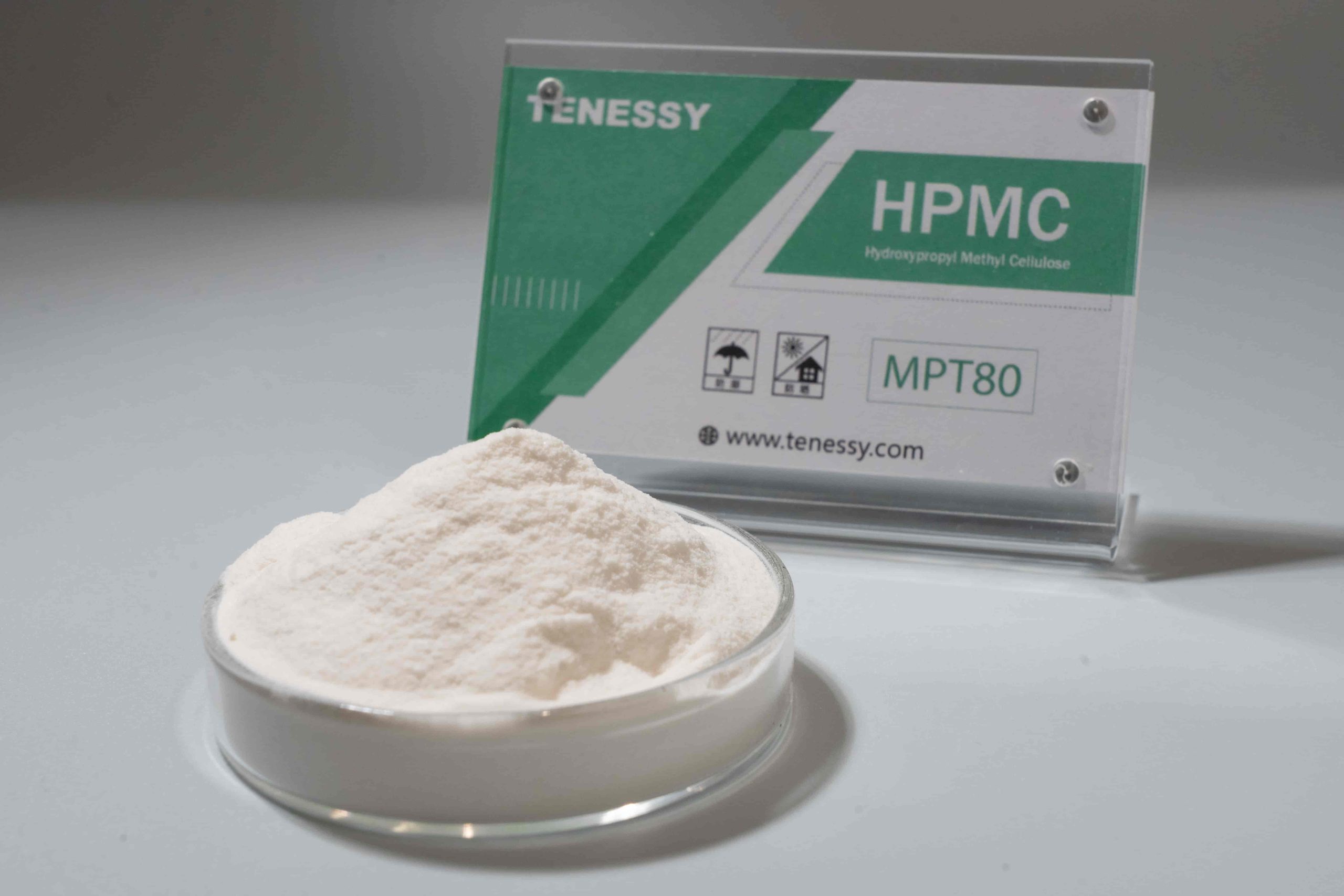

HPMC MPT80

High viscosity grade offering excellent crack resistance, superior bonding, and dense surface finishing results.

Performance Advantages of TENESSY HPMC

- Excellent Water Retention: Reduces water loss for proper hydration and uniform drying, preventing cracking and chalking.

- Improved Workability & Spreadability: Provides a smooth, creamy consistency for easy troweling and even film formation.

- Strong Adhesion & Cohesion: Enhances bonding strength to cement, plaster, or concrete for lasting durability.

- Crack & Shrinkage Resistance: Increases elasticity and reduces shrinkage stress to prevent drying cracks.

- Uniform Surface Finish: Produces a dense, smooth, defect-free surface ready for painting or finishing.

- Stable Rheology: Maintains consistent viscosity and prevents segregation during production and storage.

Other HPMC Applications

Tennessee Hydroxypropyl Methylcellulose (HPMC) improves the workability, water retention, and bonding strength of various building materials, delivering reliable performance in self leveling, wall putties, gypsum plaster, exterior insulation and finish systems (EIFS), and other dry-mix products.

Collaborating with Tennessee—Your Trusted Cellulose Ether Manufacturer

Why Choose TENESSY as Your HPMC Supplier

Reliable Quality & Consistency

Strict control of viscosity, purity, and moisture content ensures stable product performance across every batch.

Technical Expertise & Support

Our professional R&D team offers formulation optimization, lab testing, and on-site technical guidance.

Tailored Formulation Solutions

We provide HPMC grades designed to meet specific formulation goals — from economy-grade putty to premium decorative finishes.

Stable Supply & Global Delivery

With large-scale manufacturing and efficient logistics, TENESSY guarantees reliable supply for customers worldwide.

Packaging & Storage

- Packaging: 25 kg multi-layer kraft paper bag with PE inner liner.

- Pallet: 1,000 kg per pallet, securely wrapped.

- Storage: Store in a cool, dry place away from moisture and direct sunlight.

- Shelf Life: 24 months in unopened original packaging under proper storage conditions.

Free HPMC Sample

Test how TENESSY HPMC enhances the performance of your wall putty formulations.

Contact us today to request a free sample or get technical consultation from our experts. We’ll help you create wall putty with superior smoothness, excellent adhesion, and long-lasting durability.

PREGUNTAS FRECUENTES

Contactar y seguirnos

Más información

Por favor, indíqueme sus necesidades o cualquier duda, se las resolveremos.

Productos

TENESSY

Información de contacto

- info@tenessy.com

- +86 131 5618 5750

- Oficina 1523, Edificio 1 y Edificio 2, Rongsheng Times International Plaza, Calle Beiyuan nº 9, Distrito de Licheng, Jinan, Shandong

PROVEEDOR DE ÉTER DE CELULOSA

TENESSY cuenta con más de 10 años de experiencia en producción y equipos de producción avanzados.

Contacto en Whatsapp

Contacte con nosotros en WeChat

Póngase en contacto con nosotros

Rellene para obtener una muestra gratuita o consulte para más información.