HPMC لـ EIFS

Tenessy - Stronger EIFS Solutions

Tenessy HPMC for Exterior Insulation and Finish Systems

تينيسي Hydroxypropyl Methylcellulose (HPMC) is a high-quality, non-ionic cellulose ether derived from natural cotton cellulose. It is designed to improve the performance, consistency, and workability of EIFS (Exterior Insulation and Finish Systems) — a multi-layered wall system widely used for energy-efficient building facades.

In EIFS, HPMC plays a vital role in adhesive mortars, base coats, and finishing layers, improving water retention, sag resistance, bonding strength, and overall system durability.

TENESSY offers customized HPMC grades to meet different formulation requirements and climate conditions, ensuring optimal performance from mixing to long-term service life.

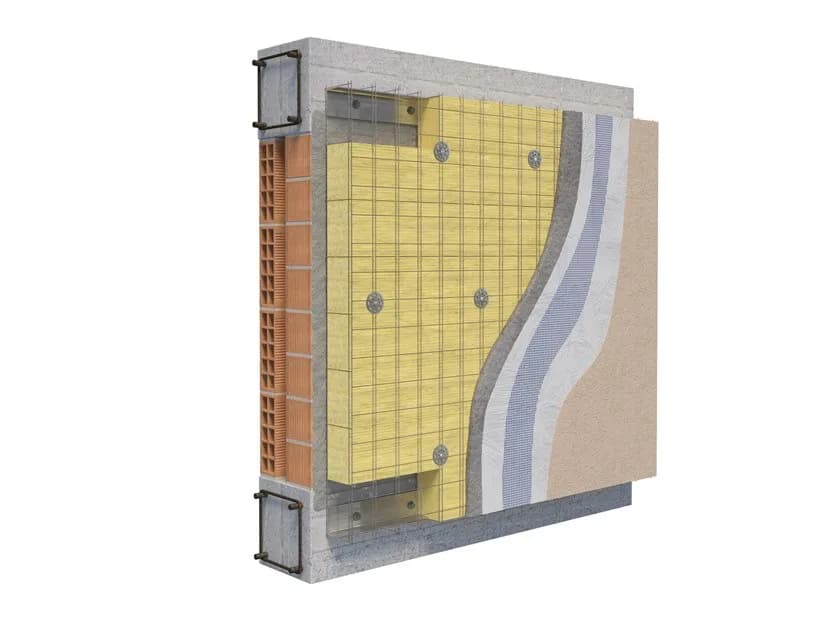

Understanding EIFS and Its Composition

EIFS is an advanced exterior wall insulation system consisting of multiple layers that together provide thermal insulation, weather protection, and decorative finishing.

Typical EIFS layers include:

- Adhesive Mortar: Bonds insulation boards (e.g., EPS, XPS) to the substrate.

- Insulation Layer: Provides thermal efficiency and energy savings.

- Base Coat with Reinforcing Mesh: Protects against impact and cracking.

- Finishing Coat: Offers aesthetic appeal and weather resistance.

Each layer requires high-quality polymer binders and functional additives — and HPMC is one of the most essential components for system stability and application performance.

The Role of HPMC in EIFS

1. Adhesive Mortar

- Improves water retention for better cement hydration and bonding to EPS/XPS boards.

- Provides excellent workability and open time for easier board placement.

- Prevents sagging or slipping of insulation panels.

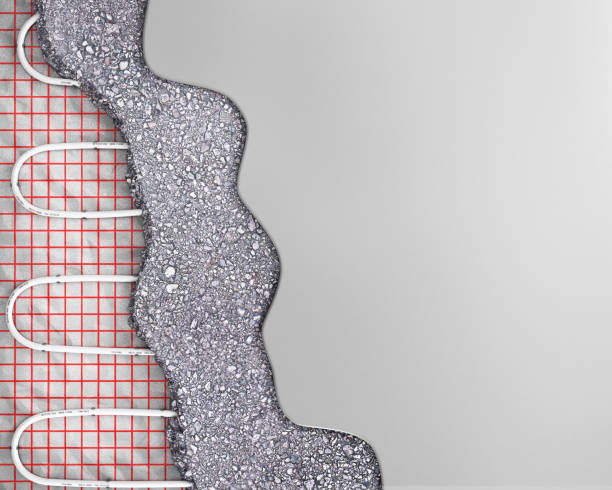

2. Base Coat (Reinforcement Layer)

- Enhances viscosity and cohesion, ensuring the mesh stays properly embedded.

- Increases crack resistance and durability under thermal movement.

- Provides smooth troweling and uniform film formation.

3. Finishing Coat

- Stabilizes consistency and improves spreadability.

- Enhances adhesion and surface smoothness, reducing peeling or uneven texture.

- Promotes film-forming properties for better water and weather resistance.

Recommended HPMC Grades for EIFS

HPMC MPT100

Medium viscosity grade designed for good water retention and open time in EIFS adhesives.

HPMC MPT150

Balanced viscosity grade offering strong cohesion, crack resistance, and easy troweling for base coats.

HPMC MPT200

High viscosity grade ensuring superior sag resistance, bonding strength, and stability for premium EIFS systems.

Key Benefits of Using TENESSY HPMC in EIFS

- احتباس ممتاز للماء: Maintains moisture during cement hydration, ensuring strong bonding and uniform curing across all EIFS layers.

- Superior Workability and Open Time: Improves smoothness and ease of application, allowing efficient work even in high temperatures.

- Anti-Sag and Slip Resistance: Enhances mortar stability and prevents insulation boards from sliding after installation.

- Enhanced Adhesion and Strength: Strengthens bonding between insulation panels, base coats, and substrates for lasting performance.

- Crack and Shrinkage Control: Adds flexibility and impact resistance to minimize cracks from thermal movement or substrate stress.

- Stable Rheology and Mixing Consistency: Ensures smooth, uniform mixtures with consistent viscosity during production and application.

Other HPMC Applications

Tennessee Hydroxypropyl Methylcellulose (HPMC) improves the workability, water retention, and bonding strength of various building materials, delivering reliable performance in self leveling, wall putties, gypsum plaster, exterior insulation and finish systems (EIFS), and other dry-mix products.

Partner with TENESSY — Your Reliable Cellulose Ether Supplier

Why Choose TENESSY for EIFS Applications

Industry-Focused Expertise

Over 15 years of experience in cellulose ether production for construction chemicals and drymix materials.

Consistent Product Quality

Strict viscosity and moisture control ensure batch-to-batch stability for manufacturers.

Formulation Support

Our technical team assists in selecting the most suitable grade and optimizing your EIFS formula.

Reliable Supply Chain

Global delivery capability with secure packaging and continuous stock availability for long-term partnerships.

Packaging & Storage

- Packaging: 25 kg multi-layer kraft paper bag with PE inner liner.

- Pallet: 1,000 kg per pallet, wrapped for stability.

- Storage: Store in a cool, dry environment, away from moisture and direct sunlight.

- Shelf Life: 24 months under proper storage conditions.

Free HPMC Sample

Experience how TENESSY HPMC improves adhesion, consistency, and durability in EIFS systems.

Contact us to request a free sample or speak with our technical experts to optimize your formulation for local conditions.

FAQ

It enhances water retention, adhesion, and workability while preventing sagging and cracking in all EIFS layers.

Typically between 0.2%–0.5% of total dry mix weight, depending on viscosity and binder type.

Yes. Its superior water retention ensures consistent performance even under fast-drying conditions.

Absolutely. We tailor viscosity, substitution degree, and particle size to meet your production and climate needs.