HPMC لـ EIFS

تينيسي - حلول EIFS أقوى - أقوى حلول EIFS

تينيسي HPMC لأنظمة العزل الخارجي والتشطيبات الخارجية

تينيسي هيدروكسي بروبيل ميثيل سيليلوز (HPMC) هو إيثر سليلوز سليلوز غير أيوني عالي الجودة مشتق من سليلوز القطن الطبيعي. وهو مصمم لتحسين أداء واتساق وقابلية تشغيل أنظمة العزل والتشطيبات الخارجية (EIFS) - نظام حائط متعدد الطبقات يستخدم على نطاق واسع لواجهات المباني الموفرة للطاقة.

في EIFS، يلعب HPMC دورًا حيويًا في الملاط اللاصق، والمعاطف الأساسية، وطبقات التشطيب, وتحسين احتباس الماء ومقاومة الترهل وقوة الترابط ومتانة النظام بشكل عام.

عروض تينيسي درجات HPMC المخصصة لتلبية متطلبات التركيبات المختلفة والظروف المناخية المختلفة، مما يضمن الأداء الأمثل بدءًا من الخلط وحتى عمر الخدمة طويل الأجل.

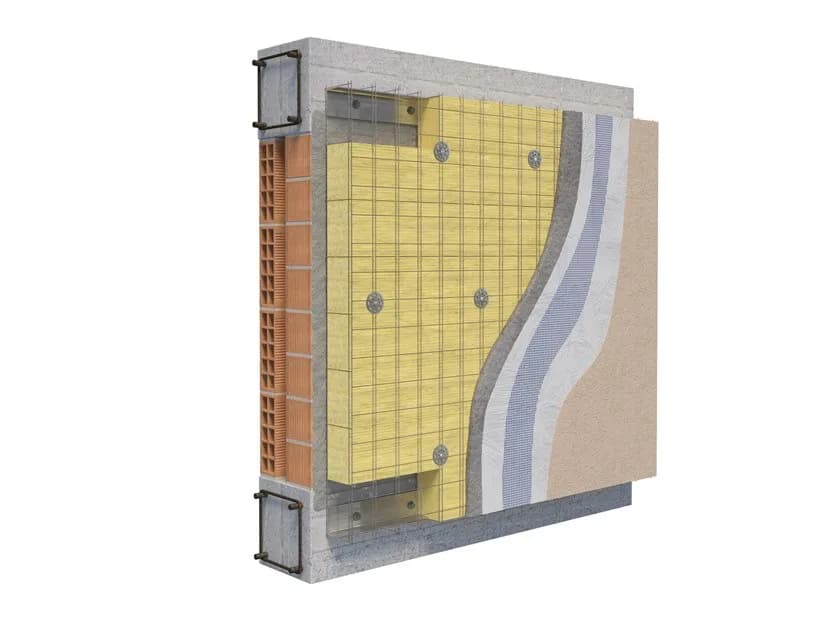

فهم نظام EIFS وتكوينه

EIFS هو نظام عزل خارجي متطور للجدران الخارجية يتكون من طبقات متعددة توفر معاً العزل الحراري والحماية من الطقس والتشطيبات الزخرفية.

تشمل طبقات EIFS النموذجية ما يلي:

- هاون لاصق: يربط ألواح العزل (مثل EPS، XPS) بالركيزة.

- طبقة العزل: يوفر الكفاءة الحرارية وتوفير الطاقة.

- طلاء قاعدي مع شبكة تقوية: يحمي من الصدمات والتشقق.

- طبقة الطلاء النهائي: يوفر مظهرًا جماليًا جذابًا ومقاومًا للعوامل الجوية.

تتطلب كل طبقة مواد رابطة بوليمرية عالية الجودة وإضافات وظيفية - و HPMC أحد أهم المكونات الأساسية لاستقرار النظام وأداء التطبيق.

دور شركة HPMC في نظام EIFS

1. ملاط لاصق

- يحسن من احتباس الماء لتحسين ترطيب الأسمنت والالتصاق بألواح EPS/XPS.

- يوفر قابلية تشغيل ممتازة ووقت فتح ممتاز لتسهيل وضع اللوح.

- يمنع ترهل أو انزلاق ألواح العزل.

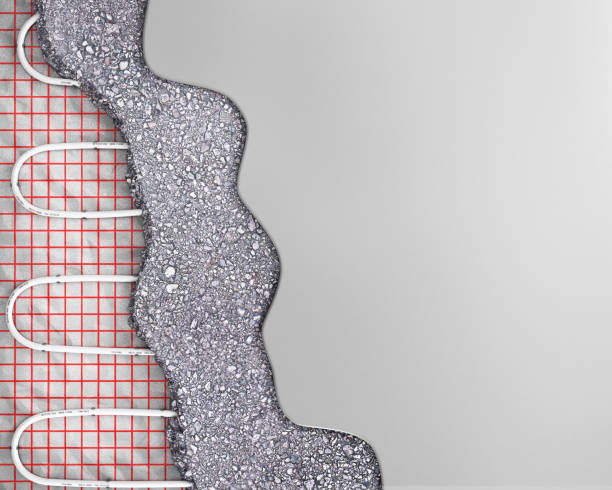

2. طبقة القاعدة (طبقة التعزيز)

- يعزز اللزوجة والتماسك، مما يضمن بقاء الشبكة مدمجة بشكل صحيح.

- يزيد من مقاومة التشققات والمتانة في ظل الحركة الحرارية.

- يوفر دكًا سلسًا وتكوين غشاء موحد.

3. طلاء التشطيب

- يثبت القوام ويحسن قابلية الانتشار.

- يعزز الالتصاق ونعومة السطح، مما يقلل من التقشير أو الملمس غير المتساوي.

- يعزز خصائص تشكيل الأغشية لتحسين مقاومة الماء والعوامل الجوية.

درجات HPMC الموصى بها لـ EIFS

HPMC MPT100

درجة لزوجة متوسطة مصممة للاحتفاظ بالماء بشكل جيد ووقت فتح جيد في المواد اللاصقة EIFS.

HPMC MPT150

درجة لزوجة متوازنة توفر تماسكاً قوياً ومقاومة للتشققات وسهولة في الطلاء الأساسي.

HPMC MPT200

درجة لزوجة عالية تضمن مقاومة فائقة للترهل وقوة الترابط والثبات لأنظمة EIFS المتميزة.

المزايا الرئيسية لاستخدام TENESSY HPMC في مواد التثبيت المائي والصناعي

- احتباس ممتاز للماء: يحافظ على الرطوبة أثناء ترطيب الأسمنت، مما يضمن ترابطاً قوياً ومعالجة موحدة في جميع طبقات EIFS.

- قابلية تشغيل فائقة ووقت مفتوح: يحسن من سلاسة وسهولة الاستخدام، مما يسمح بالعمل بكفاءة حتى في درجات الحرارة العالية.

- مقاومة الترهل ومقاومة الانزلاق: يعزز ثبات الملاط ويمنع انزلاق ألواح العزل بعد التركيب.

- تعزيز الالتصاق والقوة: يقوي الترابط بين الألواح العازلة والطبقات الأساسية والركائز للحصول على أداء يدوم طويلاً.

- التحكم في التشقق والانكماش: يضيف مرونة ومقاومة للصدمات لتقليل التشققات الناتجة عن الحركة الحرارية أو إجهاد الركيزة.

- الريولوجيا المستقرة وتماسك الخلط: يضمن خلطات سلسة وموحدة مع لزوجة ثابتة أثناء الإنتاج والاستخدام.

تطبيقات HPMC الأخرى

يحسّن هيدروكسي بروبيل ميثيل سلولوز تينيسي (HPMC) من قابلية التشغيل واحتباس الماء وقوة الترابط لمواد البناء المختلفة، مما يوفر أداءً موثوقًا في معاجين التسوية الذاتية ومعجون الجدران وجص الجبس وأنظمة العزل والتشطيبات الخارجية (EIFS) وغيرها من منتجات الخلط الجاف.

الشراكة مع TENESSY - مورد الأثير السليلوزي الموثوق به

لماذا تختار TENESSY لتطبيقات EIFS

الخبرة التي تركز على الصناعة

أكثر من 15 عامًا من الخبرة في إنتاج الإيثر السليلوزي لمواد البناء الكيميائية ومواد الخلط الجاف.

اتساق جودة المنتج

تضمن اللزوجة الصارمة والتحكم الصارم في الرطوبة ثباتاً من دفعة إلى أخرى للمصنعين.

دعم التركيبات

يساعدك فريقنا الفني في اختيار الدرجة الأنسب وتحسين تركيبة EIFS الخاصة بك.

سلسلة توريد موثوقة

قدرة توصيل عالمية مع تغليف آمن وتوافر مخزون مستمر للشراكات طويلة الأجل.

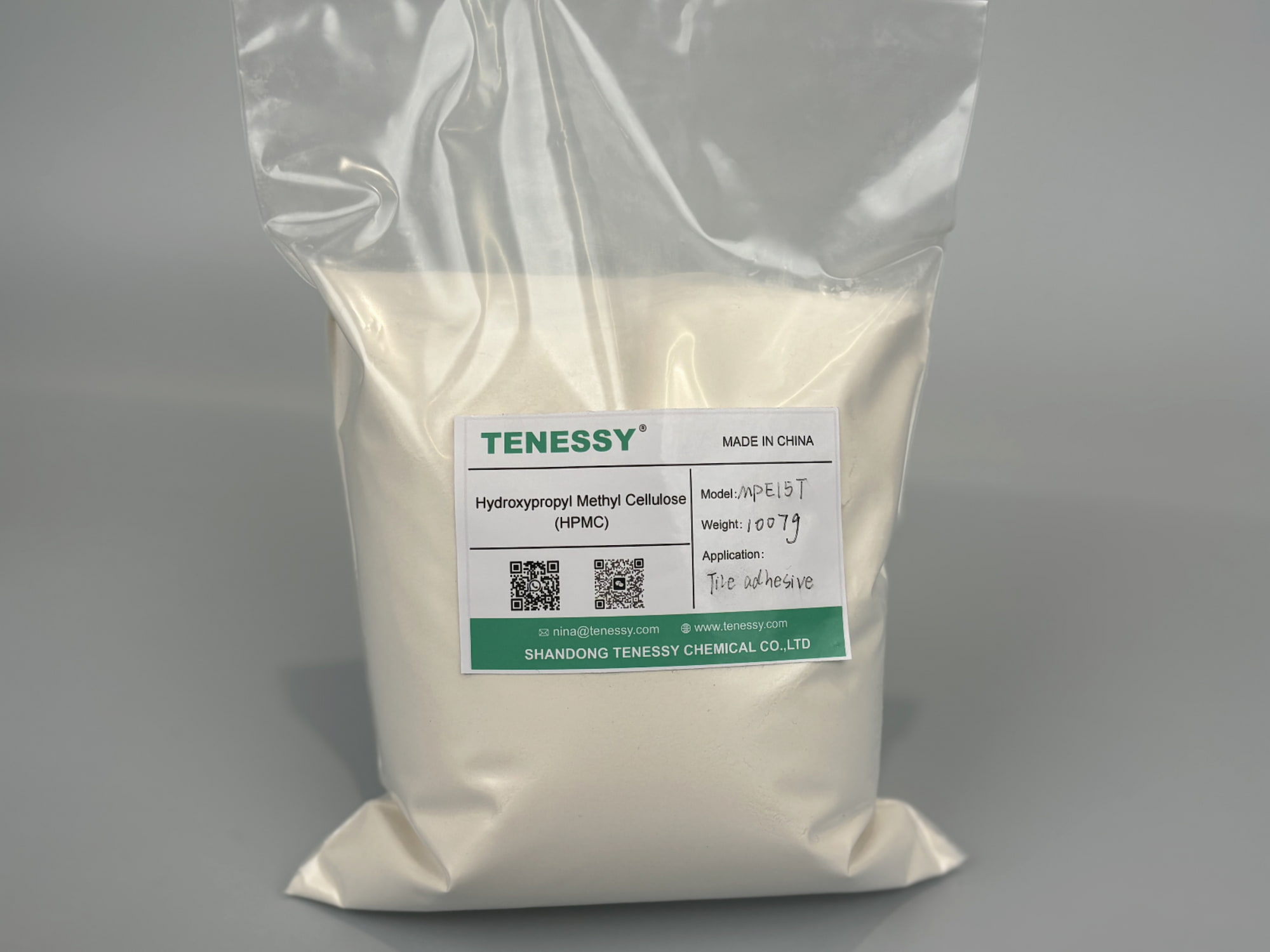

التعبئة والتغليف والتخزين

- التعبئة والتغليف: كيس ورق كرافت متعدد الطبقات بوزن 25 كجم مع بطانة داخلية من البولي إيثيلين.

- منصة نقالة: 1,000 كجم لكل منصة نقالة، ملفوفة من أجل الثبات.

- التخزين: يُحفظ في بيئة باردة وجافة بعيداً عن الرطوبة وأشعة الشمس المباشرة.

- مدة الصلاحية: 24 شهراً في ظروف تخزين مناسبة.

عينة مجانية من HPMC

جرّب كيف يحسّن TENESSY HPMC من الالتصاق والاتساق والمتانة في أنظمة EIFS.

اتصل بنا لـ اطلب عينة مجانية أو تحدث مع خبرائنا الفنيين لتحسين التركيبات الخاصة بك للظروف المحلية.

الأسئلة الشائعة

يعزز احتباس الماء والالتصاق وقابلية التشغيل مع منع الترهل والتشقق في جميع طبقات EIFS.

عادةً ما يتراوح بين 0.2%-0.5% من إجمالي وزن الخليط الجاف، اعتمادًا على اللزوجة ونوع المادة الرابطة.

نعم، يضمن احتفاظه الفائق بالماء أداءً ثابتاً حتى في ظروف الجفاف السريع.

بالتأكيد. نقوم بتكييف اللزوجة ودرجة الاستبدال وحجم الجسيمات لتلبية احتياجاتك الإنتاجية والمناخية.